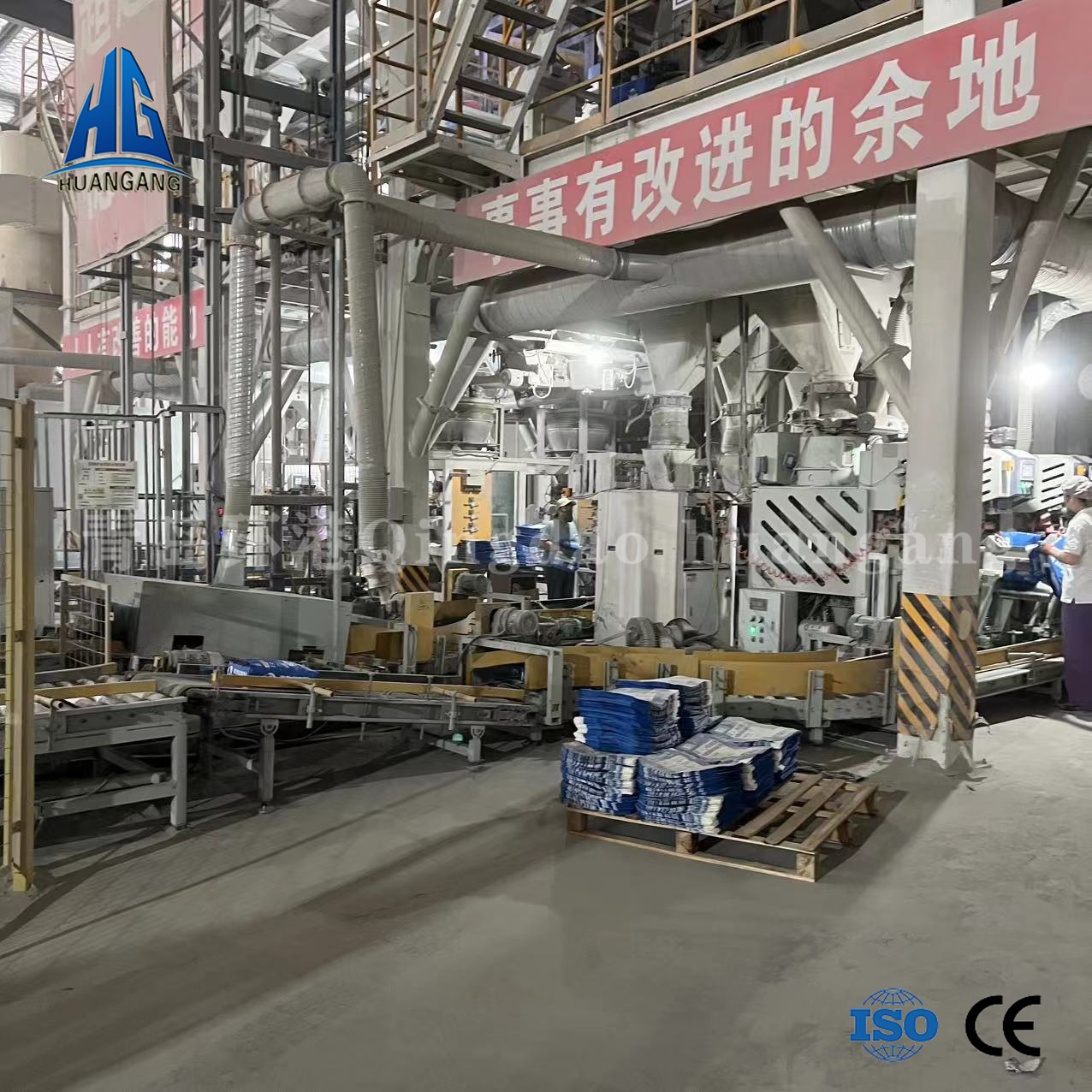

Concrete mixing plant composite production line

Category : Special mortar production line

Release Date : 2025-06-24

View : 441times

Qingdao Huan Gang has developed a dry mortar and concrete composite production line in response to the fact that some enterprises in the market produce both dry-mixed mortar and ready-mixed concrete simultaneously. This line combines the functions of both.

Some enterprises need to produce both dry-mixed mortar and ready-mixed concrete simultaneously. Therefore, they have developed dry mortar and concrete composite production lines, which combine the functions of both.

The core features of the compound production line:

Dual-mode production: The same system can switch between dry-mixed mortar and concrete production modes, improving equipment utilization.

Raw material sharing: Powder silos for cement, fly ash, etc. can be shared, reducing repetitive investment.

Intelligent switching: Adjust the batching and mixing processes through PLC control to meet the requirements of different products.

Modular design: Specialized equipment for dry-mixed mortar or concrete can be expanded as needed (such as adding a sand drying system).

✅ Save investment: One set of equipment meets two production needs, reducing plant and hardware input.

✅ Flexible production: Adjust product structure according to market demand (e.g. Concrete in peak season, dry mortar in off-peak season).

✅ Resource optimization: Shared powder storage, dust removal system, etc. to reduce energy consumption and maintenance costs.

✅ Environmental Compliance: Integrated dry mortar dust control and concrete wastewater recycling to meet environmental requirements.

The advantages of high-quality after-sales service

• Extend equipment lifespan: Standardized maintenance can reduce wear and tear and prevent major malfunctions.

• Reduce operating costs: Preventive maintenance is less costly than post-repair.

• Ensure production continuity: Quick maintenance reduces downtime losses, especially suitable for continuous operation scenarios such as commercial concrete mixing stations.

• Compliance support: Assist customers in passing environmental protection and safety annual inspections (such as dust removal system tests).

Ready-mixed dry mortar production line

Ready-mixed dry mortar production line An annual output of 100,000 tons of putty powder complete production line

An annual output of 100,000 tons of putty powder complete production line HUANGANG Putty powder production equipment

HUANGANG Putty powder production equipment External wall putty powder production line

External wall putty powder production line Light plaster plaster equipment/plaster base self-leveling mortar production line

Light plaster plaster equipment/plaster base self-leveling mortar production line Light weight gypsum mortar production equipment

Light weight gypsum mortar production equipment