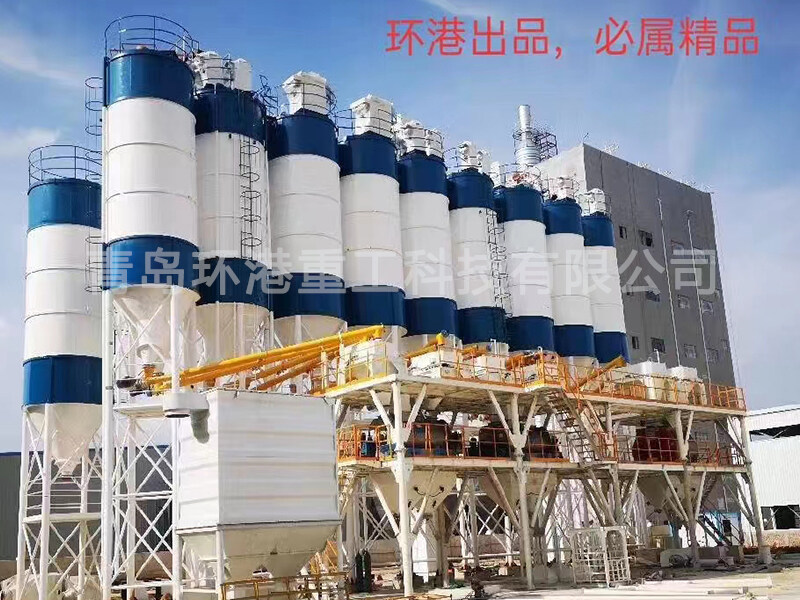

Light plaster plaster equipment/plaster base self-leveling mortar production line

Category : Gypsum mortar production line

Release Date : 2025-05-08

View : 3092times

The gypsum-based self-leveling mortar production line is an automated equipment system specially designed for the production of high-quality self-leveling mortar. It adopts advanced dry-mixing process technology and can produce both ordinary and fast-setting gypsum-based self-leveling products. This production line is composed of a raw material pretreatment system, a precise metering system, an efficient mixing system, a finished product packaging system and an intelligent control system, with a standard production capacity of 3 to 30 tons per hour.

Lightweight gypsum, putty powder, special mortar multi-functional production line:

1. Compact structure, small footprint;

2. Less investment, fast return;

3. Can produce light gypsum, gypsum mortar, putty powder, special mortar and other products;

4. Can be installed in the standard industrial plant, simple and flexible.

Note: The above figures are based on double shifts of 16 hours per day, 300 days per year.

1, high degree of automation: through the total control system, all raw materials (including additives) automatic metering, automatic transportation, automatic mixing, automatic packaging, automatic transportation, automatic palletizing molding, the entire production process without manual participation, greatly reducing labor costs.

Second, no dust: the whole equipment is divided into the whole, fixed-point two dust removal methods, in the dust concentration area using fixed-point dust removal recovery, other areas using the overall dust removal recovery, to create a standardized workshop.

Good stability: our company has many years of industry experience in absorbing putty powder equipment, and every detail and every process of the complete production line have been strictly calculated and debugged by our technical department to ensure the production capacity and stability of the entire line.

Professional engineers will provide full guidance throughout the installation and commissioning process

Provide 5 to 7 days of system operation training

24-hour technical hotline support

Ready-mixed dry mortar production line

Ready-mixed dry mortar production line An annual output of 100,000 tons of putty powder complete production line

An annual output of 100,000 tons of putty powder complete production line HUANGANG Putty powder production equipment

HUANGANG Putty powder production equipment External wall putty powder production line

External wall putty powder production line Light plaster plaster equipment/plaster base self-leveling mortar production line

Light plaster plaster equipment/plaster base self-leveling mortar production line Light weight gypsum mortar production equipment

Light weight gypsum mortar production equipment