Category : Automatic stretch HoodingMachine

Release Date : 2025-05-14

View : 957times

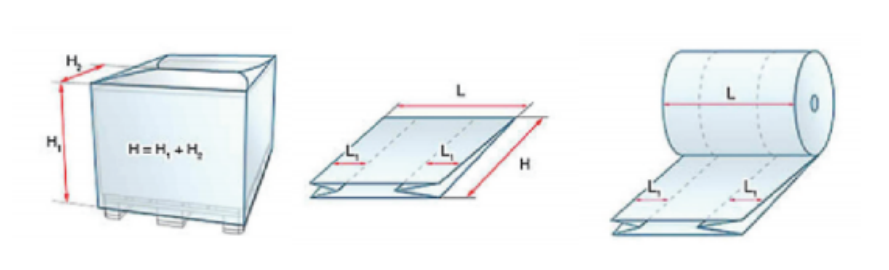

The stretch hooding process gently expands tubular stretch film and smoothlycovers palletized goods from top to bottom, tightly securing items using thefilm's natural elasticity. Unlike conventional stretch wrapping methods, stretchhooding cuts down film replacement intervals by as much as ten times andsignificantly enhances resistance to tearing and punctures. Besides securelyholding pallet loads together, the hooding process provides effectiveprotection against dust, moisture, and product spillage, keeping your packagedgoods in pristine condition throughout transportation and storage.

|

Jacket station conveyor length |

1500mm+2000mm+1500mm |

|

Envelope velocity |

170 mm/s |

|

Operating voltage |

AC 380V/3相5线/50Hz |

|

Overall power |

≈20 kW' |

|

International pallet specifications (stack size) packaging machine mainly for these two specifications |

1100mm*1300mm、1000mm*1200mm, 其他规格可定制 |

|

Stack height |

500mm-2250mm |

|

Packing speed |

小于等于60托盘/PH |

Note: This product is constantly improved with the progress of technology, the above listed parameters and structural characteristics and the real difference between the actual design and the real shall prevail.

Its user-friendly visual interface simplifies parameter adjustments, offering intuitive operation and easy maintenance.

Ready-mixed dry mortar production line

Ready-mixed dry mortar production line An annual output of 100,000 tons of putty powder complete production line

An annual output of 100,000 tons of putty powder complete production line HUANGANG Putty powder production equipment

HUANGANG Putty powder production equipment External wall putty powder production line

External wall putty powder production line Light plaster plaster equipment/plaster base self-leveling mortar production line

Light plaster plaster equipment/plaster base self-leveling mortar production line Light weight gypsum mortar production equipment

Light weight gypsum mortar production equipment