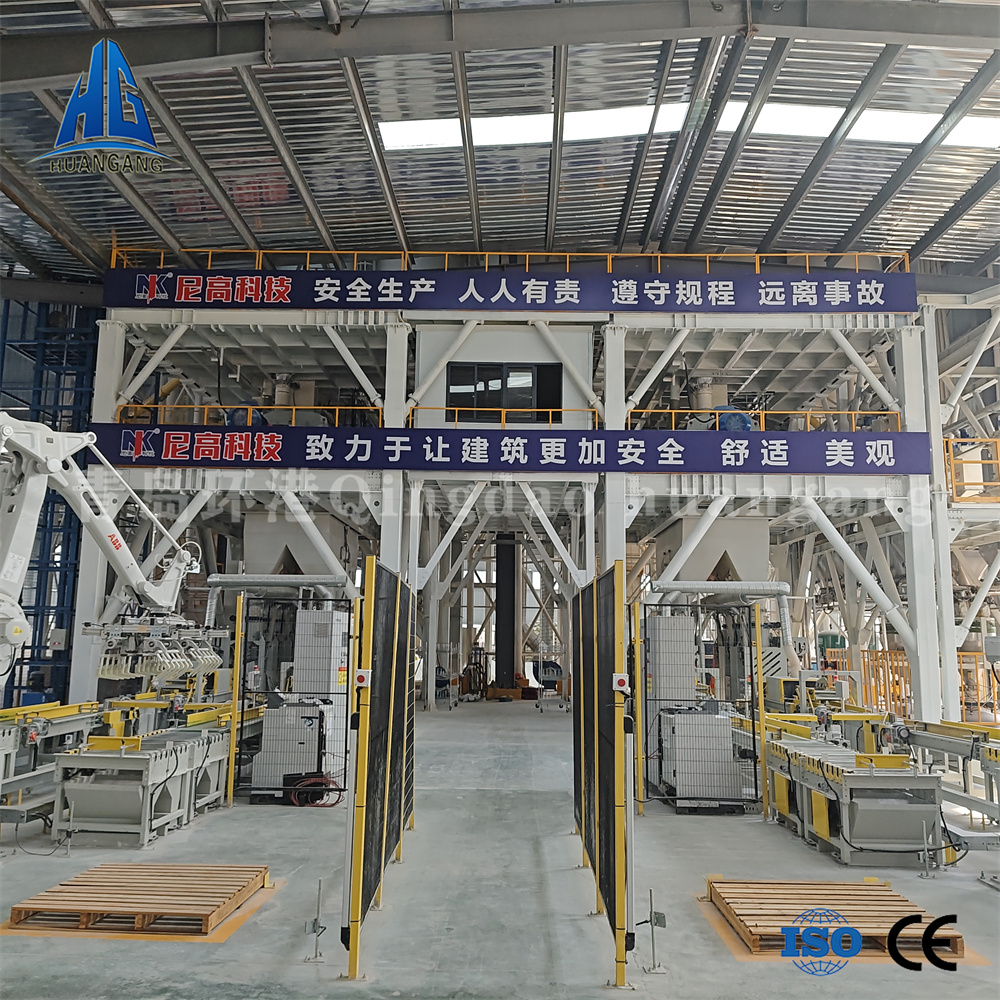

Qingdao HUANGANG Gypsum-based Mortar Equipment

Category : Gypsum mortar production line

Release Date : 2025-05-06

View : 749times

Gypsum mortar production line is a complete set of equipment specially used for the production of limestone mortar, covering the whole process from raw material treatment to finished product packaging. Here are the details:

Raw material storage system: Used to store raw materials such as quartz, sand and additives, usually including silos and conveying equipment.

Measurement system: accurate measurement of each raw material, to ensure the accurate ratio, commonly used electronic scale or spiral meter.

Mixing system: the core part, the raw materials are evenly mixed, commonly used dual-axis non-gravity mixer or plow knife mixer packaging system: the finished mortar automatic packaging, commonly used valve pocket packaging machine or open pocket packaging machine.

Control system: Automatic control, improve production efficiency, commonly used PLC control system.

Efficient mixing: ensure that the mortar is uniform and the quality is stable.

High degree of automation: reduce labor, improve efficiency.

Environmental protection and energy saving: low energy consumption, good dust control.

Easy operation: friendly interface and easy maintenance.

Stable quality: automatic production, consistent quality.

High production efficiency: continuous production, large output.

Environmental protection: low emissions, in line with environmental requirements.

1. Installation and commissioning

On-site installation: The supplier sends a professional team to the site to install the equipment to ensure correct installation.

Equipment commissioning: debugging after installation to ensure normal operation of the equipment and meet the design requirements.

2. Operation training

Operation training: Provide training to the customer's operation and maintenance personnel to ensure that they can operate the equipment proficiently.

Technical training: Provide equipment principle, maintenance, troubleshooting and other technical training.

3. Perform regular maintenance

Regular inspection: Regularly send technical personnel to check the equipment to ensure normal operation.

Preventive maintenance: Provides preventive maintenance services to reduce failures.

Ready-mixed dry mortar production line

Ready-mixed dry mortar production line An annual output of 100,000 tons of putty powder complete production line

An annual output of 100,000 tons of putty powder complete production line HUANGANG Putty powder production equipment

HUANGANG Putty powder production equipment External wall putty powder production line

External wall putty powder production line Light plaster plaster equipment/plaster base self-leveling mortar production line

Light plaster plaster equipment/plaster base self-leveling mortar production line Light weight gypsum mortar production equipment

Light weight gypsum mortar production equipment