Qingdao HUANGANG inner wall coating production equipment

Category : Putty powder production line

Release Date : 2025-05-06

View : 738times

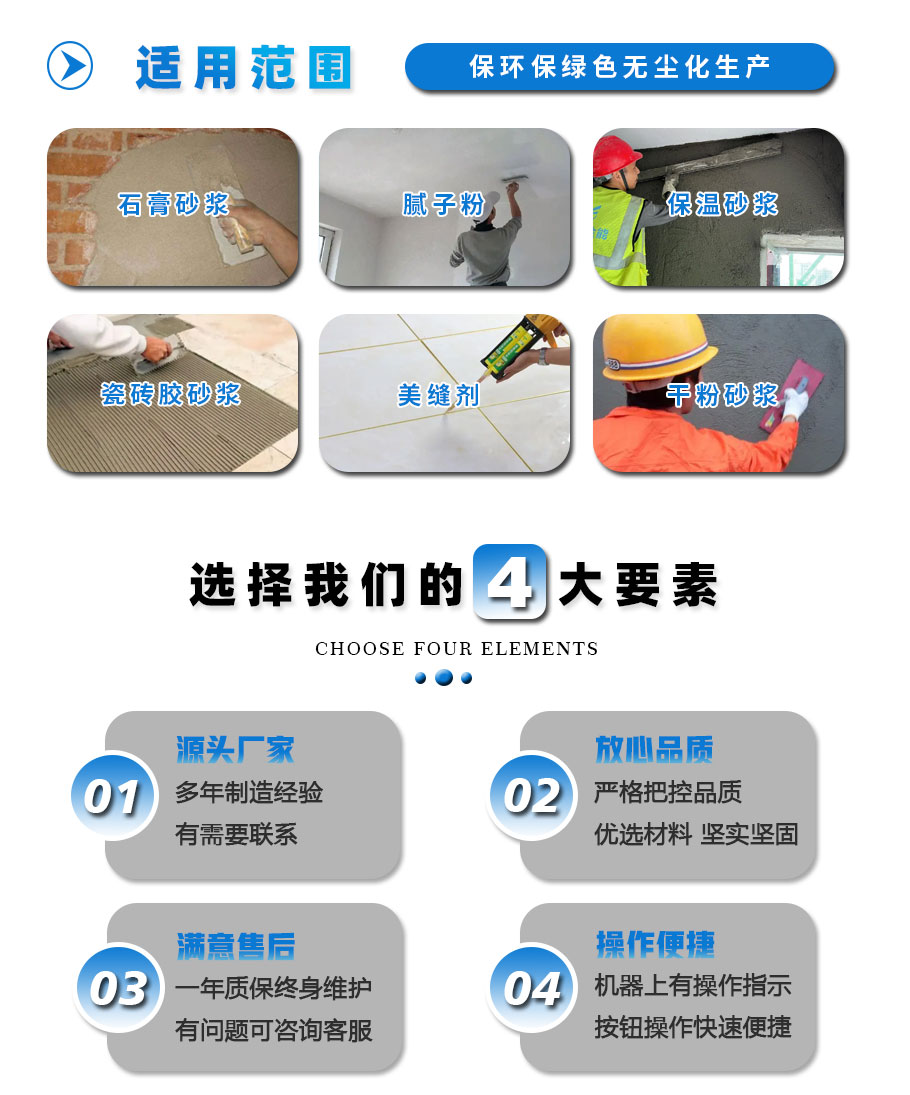

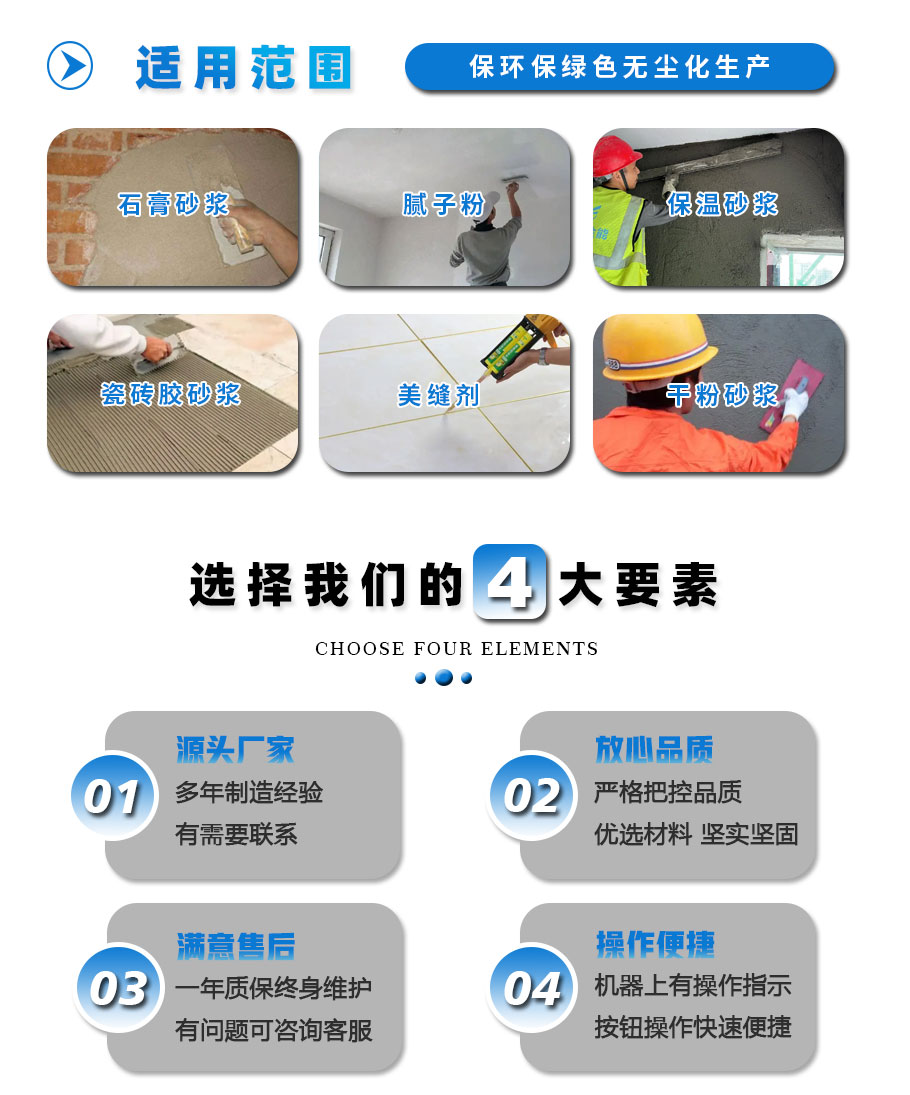

The typical putty powder production line is used for raw material storage - metering batching - material mixing - finished product packaging, as well as production equipment such as raw material transportation, lifting and dust removal in the putty powder production process.

The working principle of the putty powder production line is mainly to mix and stir various raw materials, and then enter the finished product warehouse, connect the packaging device for bagging, and put into the production to achieve the repeated operation of the assembly line.

Putty powder production line through the automatic, continuous production mode, greatly improve the production efficiency, reduce the labor cost. At the same time, the precise dosing system and the efficient mixer ensure the product quality of the putty powder. In addition, the dust removal system is also conducive to environmental protection and cleaner production.

In summary, putty powder production line is an important equipment for the production of putty powder, its composition is complex and fine, with high efficiency, environmental protection, high degree of automation advantages. In practical application, the appropriate production line type and configuration scheme should be selected according to the production demand and actual situation.

|

型号

|

主机类型

|

主机型号

|

小时产量/吨

|

年产量/万吨

|

|

GHZ1500

|

单轴犁刀式搅拌机

|

DZ1500

|

15-18

|

7-9

|

|

GHZ2000

|

双轴无重力搅拌机

|

SZ2000

|

20-24

|

9-11

|

|

|

单轴犁刀式搅拌机

|

DZ2000

|

20-24

|

9-11

|

|

GHZ3000

|

双轴无重力搅拌机

|

SZ3000

|

30-35

|

14-16

|

|

|

单轴犁刀式搅拌机

|

DZ3000

|

30-35

|

14-16

|

|

GHZ4000

|

双轴无重力搅拌机

|

SZ4000

|

40-45

|

19-21

|

|

|

单轴犁刀式搅拌机

|

DZ4000

|

40-45

|

19-21

|

|

GHZ6000

|

双轴无重力搅拌机

|

SZ6000

|

60-65

|

29-31

|

|

GHZ8000

|

双轴无重力搅拌机

|

SZ8000

|

80-88

|

38-42

|

1. Through the total control system, no manual automatic production can be achieved, and all raw materials (including additives) are automatically measured, transported, mixed, packaged, transported, palletized and formed.

2. The whole equipment is divided into integral and fixed-point dust removal methods. Fixed-point dust removal recovery is used in the dust concentration area, and overall dust removal recovery is used in other areas to create a standardized workshop.

3. The conveyor line is equipped with multiple processes such as shaping, cleaning, coding and thermal sealing to ensure that each bag of products has a clean and tidy appearance and a neat shape, and then neatly palletized, wrapped and coated.

4. The company can combine the specific process to provide you with investment analysis, market refinement, equipment selection, after-sales installation, personnel training, maintenance, formula support and other whole-process services

The company relies on a strong R & D design team, mature design concept, according to the customer's product formula and investment plan, optimize the process flow, tailor-made, to provide customers with economic product solutions.

From investment analysis, market refinement, equipment selection, after-sales installation, personnel training, maintenance, formula support one-stop thoughtful and meticulous service, global quality parts procurement makes your equipment stable operation.

In the face of increasingly strict background, the company optimizes the process flow, the comprehensive treatment of dust removal and emission, so that the equipment can be, energy saving and operation. Service engineers, always keep an eye on your equipment. Ensure the stable and reliable operation of your equipment to effectively reduce equipment maintenance costs.

Ready-mixed dry mortar production line

Ready-mixed dry mortar production line An annual output of 100,000 tons of putty powder complete production line

An annual output of 100,000 tons of putty powder complete production line HUANGANG Putty powder production equipment

HUANGANG Putty powder production equipment External wall putty powder production line

External wall putty powder production line Light plaster plaster equipment/plaster base self-leveling mortar production line

Light plaster plaster equipment/plaster base self-leveling mortar production line Light weight gypsum mortar production equipment

Light weight gypsum mortar production equipment