Putty powder matching palletizer

Category : Putty powder production line

Release Date : 2025-03-24

View : 669times

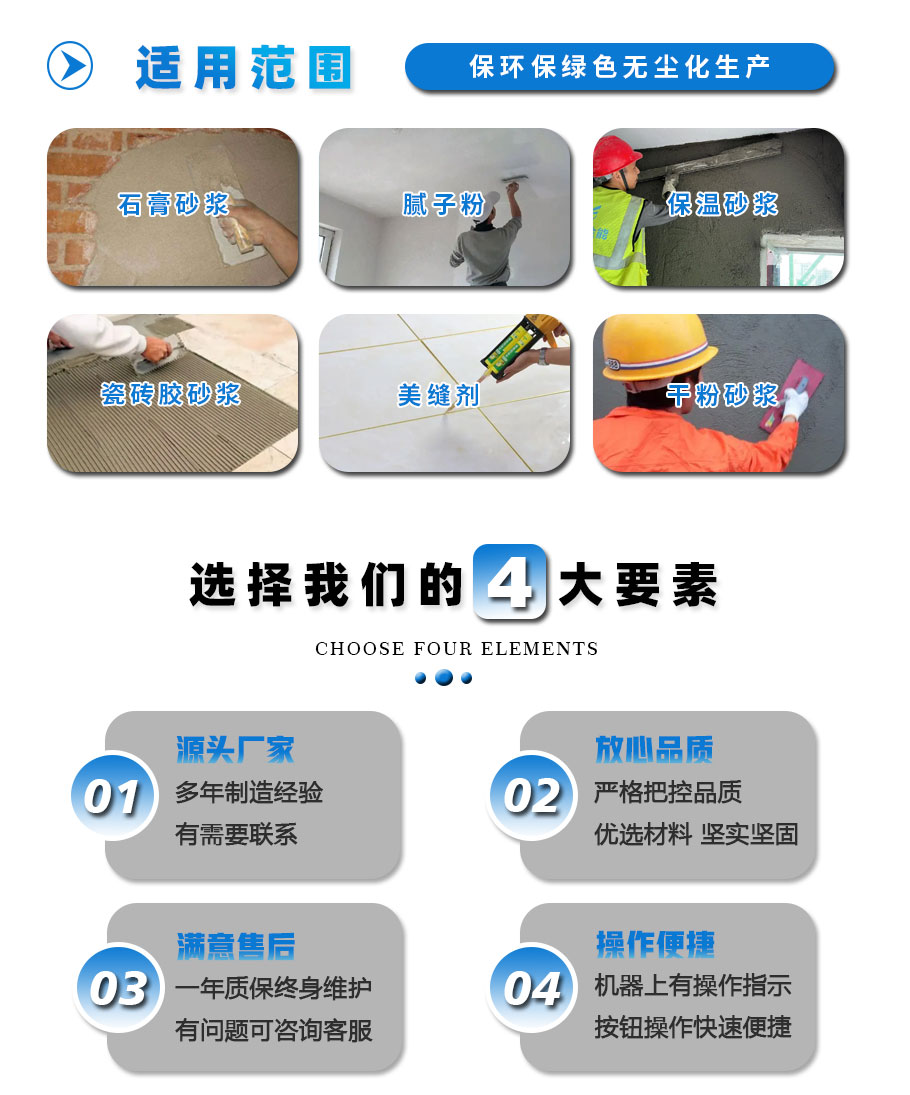

Putty powder palletizer is an automated device that can neatly stack putty powder bags on pallets according to a preset stacking pattern (such as 5 layers x 4 columns x 2 rows). It uses robotic arms, conveyor belts and control systems to work together to achieve efficient and precise palletizing operations, significantly increasing production efficiency and reducing labor costs.

1. Efficient production and cost reduction

The palletizing speed can reach 1200 bags/hour, which is 3-5 times that of manual palletizing.

Automation reduces labor costs, and one piece of equipment can replace 4-6 workers.

2. Accurate and stable, improve quality

The high-precision mechanical arm ensures that each bag of putty powder is placed neatly, and the stacking stability is high, reducing the risk of collapse during transportation.

Suitable for different specifications of putty powder bags, palletizing effect consistency.

3. Strong flexibility to adapt to diverse needs

Support a variety of stacking modes (such as 5 layers x 4 columns x 2 rows), can be customized according to customer needs.

It can be seamlessly connected with other equipment (such as packaging machine, winding machine) to achieve a fully automated production line.

Five advantages of this device, so that you can rest assured to buy, long-term use:

1. The company selected better materials and parts, high quality, cost-effective

2. The addition of this device helps you improve work efficiency and reduce labor costs

3. Complete functions to meet your various operating needs

4. Delivery on time, reduce the time cost of waiting for delivery

Qingdao Huangang Equipment Technology Co., Ltd. relies on a strong R & D design team, mature design concept, according to the customer's product formula and investment plan, optimize the process flow, tailor-made, to provide customers with economic product solutions.

From investment analysis, market refinement, equipment selection, after-sales installation, personnel training, maintenance, formula support one-stop thoughtful and meticulous service, global quality parts procurement makes your equipment stable operation.

In the face of increasingly strict background, the company optimizes the process flow, the comprehensive treatment of dust removal and emission, so that the equipment can be, energy saving and operation. Service engineers, always keep an eye on your equipment. Ensure the stable and reliable operation of your equipment to effectively reduce equipment maintenance costs.

Ready-mixed dry mortar production line

Ready-mixed dry mortar production line An annual output of 100,000 tons of putty powder complete production line

An annual output of 100,000 tons of putty powder complete production line HUANGANG Putty powder production equipment

HUANGANG Putty powder production equipment External wall putty powder production line

External wall putty powder production line Light plaster plaster equipment/plaster base self-leveling mortar production line

Light plaster plaster equipment/plaster base self-leveling mortar production line Light weight gypsum mortar production equipment

Light weight gypsum mortar production equipment