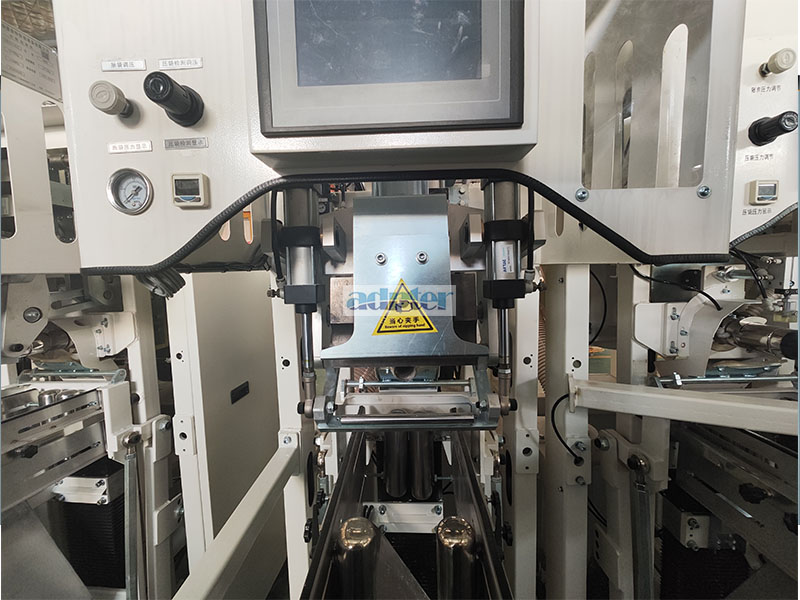

Special mortar production line packaging machine hot sealing

Category : Packaging machine accessories

Release Date : 2025-05-08

View : 1882times

Compact structure, simple and elegant appearance, simple operation, flexible movement, easy maintenance and other advantages with a wide range of frequency tracking, high accuracy of frequency tracking, ultrasonic energy instant output, strong force, fast response, safe and reliable, high control accuracy.

The main control system of the whole machine adopts imported high-speed large-capacity MCU, equipped with the latest and efficient μcos III operating system, modular management of current sampling, output port, input port, signal acquisition, high-speed communication, safety protection and fault warning functions, so that the equipment can run efficiently and stably.

Regular maintenance

Quarterly inspection services are provided, including: air tightness testing, weighing calibration, replacement of worn parts, etc

Technological upgrade

Free firmware upgrade service is provided to continuously optimize packaging accuracy and speed

Remote support

Equipped with an Internet of Things module, it supports remote diagnosis by engineers (with customer authorization), and the efficiency of fault handling is increased by 60%

Intelligent temperature control system

It adopts PID intelligent temperature control technology, with a temperature control accuracy of ±1℃. The working temperature range is adjustable from 100 to 300℃, and it is suitable for various material packaging bags (PP/PE/ composite film).

High-efficiency sealing design

The patented double-sided heating structure features automatic control in three stages: heating, pressure holding and cooling.

Regular maintenance

Quarterly inspection services are provided, including: air tightness testing, weighing calibration, replacement of worn parts, etc

Technological upgrade

Free firmware upgrade service is provided to continuously optimize packaging accuracy and speed

Remote support

Equipped with an Internet of Things module, it supports remote diagnosis by engineers (with customer authorization), and the efficiency of fault handling is increased by 60%

Ready-mixed dry mortar production line

Ready-mixed dry mortar production line An annual output of 100,000 tons of putty powder complete production line

An annual output of 100,000 tons of putty powder complete production line HUANGANG Putty powder production equipment

HUANGANG Putty powder production equipment External wall putty powder production line

External wall putty powder production line Light plaster plaster equipment/plaster base self-leveling mortar production line

Light plaster plaster equipment/plaster base self-leveling mortar production line Light weight gypsum mortar production equipment

Light weight gypsum mortar production equipment