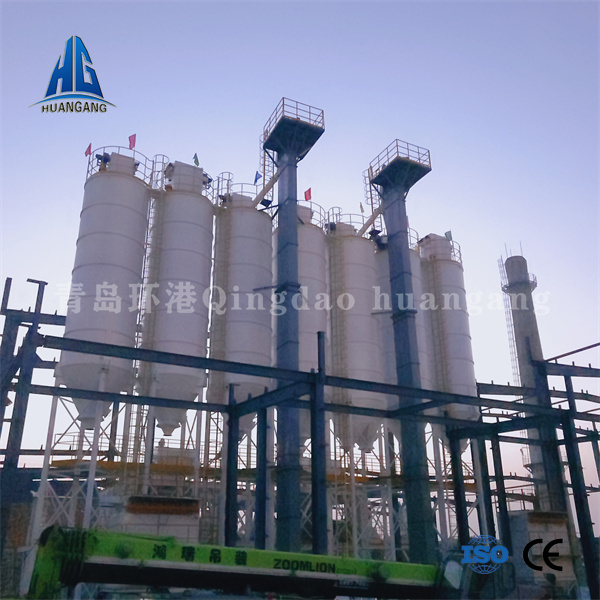

Amidst the roar of mortar equipment, the mortar equipment projects of Qingdao Huan Gang in multiple locations both at home and abroad are being carried out simultaneously. Today, let's uncover through the real lenses of our customers how the intelligent mortar production line of Qingdao Huan Gang has become a "hardcore" partner for enterprises to reduce costs and increase efficiency and win the market, and how it builds the future together with its customers.

Mortar storage tank: The raw material storage bin is used to store and supply mortar raw materials. The tank body is used to store raw materials or finished mortar. It is usually made of corrosion-resistant and wear-resistant materials, effectively preventing moisture and segregation.

Bucket elevator: Vertical conveying is stable and efficient, saving space. It lifts raw materials from a lower place to the feeding port of the storage bin and is used for conveying various types of mortar and raw materials.

Precision weighing system (weighing system/small material metering system) : The accuracy of the formula is the core of mortar quality. Our high-precision sensors, in combination with the computer-controlled weighing system, can precisely measure the usage of various raw materials during the batching process of mortar production according to the preset formula. Minimizing the error of trace components fundamentally ensures the absolute accuracy and stability of each batch of product formulas.

High-efficiency mixer: As the "heart" of the production line, Qingdao Huan Gang's gravity-free mixer/mixer is renowned for its powerful mixing capacity. It can achieve thorough and uniform mixing of materials in an extremely short time, eliminate lumps and dead corners, and ensure the uniformity of product texture. Whether it is ordinary mortar or special mortar, it can handle it with ease.

Finished product warehouse: It can conduct initial quality control of products. When the materials enter the finished product silo and are temporarily stored inside, it is possible to observe whether the dry-mixed mortar has any abnormal conditions such as stratification or caking. If any quality issues with the products are detected, the packaging and subsequent processes can be promptly halted to minimize the outflow of substandard products and provide a solid guarantee for continuous and efficient packaging operations in the future.

Intelligent central control system: The brain of the entire production line. The "central control system" of Qingdao Huan Gang has achieved "one-click" operation, with the production process, formula parameters and equipment status all clearly visible on the screen. It significantly reduces the reliance on human labor and the experience of operators, making production management simple, precise, and all data traceable.

Automated packaging and palletizing machine: Finished products are precisely measured and quickly filled by the automatic packaging machine, and the packaging opening design effectively suppresses dust. Immediately after that, the fully automatic palletizing machine replaced manual labor with mechanical arms, stacking packaging materials neatly and efficiently. This not only liberated the heavy physical labor but also raised the factory output efficiency to a new level.

Environmental protection dust collector: We always put green production first. The entire production line is fully enclosed, and high-efficiency "pulse dust collectors" are installed at each dust-generating point, just like putting a "mask" on the equipment, ensuring that the production site is clean and dust-free, fully meeting modern environmental protection requirements.

From the initial raw materials to a package of high-quality finished mortar, Qingdao Huan Gang Intelligent Mortar Equipment, with the reliability of each component and the intelligence of the entire system, not only builds a "stable, efficient, environmentally friendly and worry-free" production line for customers, but also provides a complete solution regarding efficiency, quality and the future.